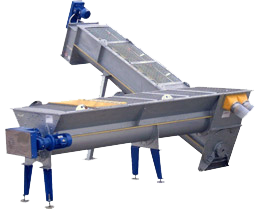

WAM Aggregate Concrete Reclaimers – CONSEP 5000

The WAM CONSEP® 5000 is used for the recovery of residual concrete and wash water from truck mixers/ concrete pumps returning to the plant after delivery.

Designed for application in concrete plants, CONSEP® 5000 excels through its efficiency, reliability, and innovative features.

The CONSEP 5000 is manufactured from galvanized carbon steel. It is made up of a U-shape trough and a large inlet batch hopper, both lined with wear-resistant SINT engineering polymer. The CONSEP 5000 comes with a wide outlet spout, a ribbon screw with individually replaceable segments coated with wear-resistant SINT engineering polymer, a bolted trough cover grid, and a robust gear motor which suits the application.

The CONSEP® 5000 is the answer to the latest environmental standards concrete manufacturers need to comply with today:

- Environmental impact

- Pollution prevention

- Recirculation of waste water

- Recycling of separated aggregates

- Maximum recycling capacity (of normal diluted concrete) up to 20 m3/h

- Separation of solid fines of up to 0.2 mm

Technical Features

- PATENTED innovative modular SINTTM engineering polymer components

- Non-stick, abrasion-resistant SINTTM engineering polymer components

- Screw with non-stick wear-resistant coating

- Trough with non-stick wear-resistant liner

- Feed control batcher

- Visual inspection and easy access

- Bottom bearing assembly

- Highly corrosion-resistant galvanised fabricated parts

- Control panel

Features

- Flow rate: 20 m3/h (12 cfm) of diluted concrete

- Drive power: 5.5 kW (7.5 HP) 220-240/380-420 V, 50 Hz; 440-480 V, 60 Hz

- All fabricated parts manufactured from galvanized carbon steel

- Heavy-duty ribbon flight screw in high-resistance steel painted and coated with wear-proof, non-stick SINT engineering polymer

- Trough and batch hopper lined with wear-proof, non-stick SINT engineering polymer

- Sturdy, extra-heavy-duty design

- Internal, replaceable maintenance-free lower bearing

Benefits

- Quick Return On Investment

- Excellent solids-liquid separation and washing of aggregates

- Reduction of maintenance costs for the End User (SINT non-stick properties and resistance to abrasion, modular components)

- Low running costs (low water and energy consumption)

- Energy savings thanks to reduced running time

- Low consumption of wash water

- Low maintenance, easy and quick

- Total feed control on discharging vehicles

- Perfect aggregate washing

- Different options to satisfy various needs

Video

Resources