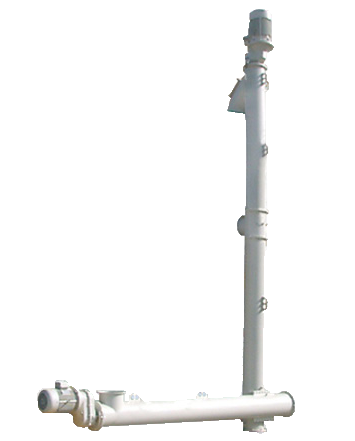

WAM Vertical Screw Conveyor – VE

Vertical screw conveyors efficiently lift bulk materials, offering space-saving design and reliable upward transport with minimal footprint.

The VE Vertical Screw Lift System consists of two units: a Horizontal Screw Feeder which receives material from a silo, hopper, or another feeder or conveyor, and a Vertical Screw Conveyor that lifts the material to a certain height.

Material may be discharged into a weigh hopper, into one or more bins or silos, or into another conveyor or conveying system.

Fabricated components, screws, and bearing assemblies are specially designed for this system to facilitate maintenance.

The VE Vertical Screw Lift System excels through high volumetric efficiency and excellent mechanical features.

Technical Specifications

The VE Vertical Screw Lift System consists of a Horizontal Screw Feeder and a Vertical Screw Conveyor.

The Horizontal Screw Feeder feeding material from a silo or hopper or conveying it fed by an upstream feeding device, consists of a U-shaped or tubular carbon steel trough with appropriate surface finishing. The outlet zone of the horizontal screw feeder consists of a short tubular section tangentially flanged at a right angle on the bottom section of the Vertical Screw Conveyor. A flange is welded at each end of the Horizontal Screw Feeder. The trough or tube contains a rotating screw with coupling bushes at each end connected with the shafts of the two end bearing assemblies. The Horizontal Screw Feeder is equipped with one or more intermediate hanger bearings should its overall length require them. Furthermore, the Horizontal Screw Feeder is equipped with a drive unit suitable for the application.

The Vertical Screw Conveyor consists of a tubular housing complete with the above-mentioned tangential inlet in the bottom section which connects with the outlet of the Horizontal Screw Feeder, an inclined outlet spout in the top section, end flanges welded on each conveyor tube section, a rotating screw in one or more sections with shaft coupling bush at each end, a base bearing assembly complete with slide bush, and a number of intermediate hanger bearings should the overall height of the conveyor require them. The top-mounted drive unit with integrated end bearing assembly (from which the screw is suspended) and self-adjusting shaft seal is suitable for the application.

The VE Vertical Screw Lift System is available in a medium heavy-duty version only.

Features

- External tube diameter: 114 mm (4.5 in), 139 mm (5.5 in), 168 mm (6.6 in), 193 mm (7.6 in), 219 mm (8.6 in), 273 mm (10.7 in), 323 mm (12.7 in)

- Elevation height in 1 metre steps (3.3 ft) up to a maximum of 20 metres (65.6 ft)

- Throughput rates: 3 m³/h (1.8 cfm) ~ 95 m3/h (56 cfm) considering volumetric efficiency of Portland cement.

- Powder-coated

Benefits

- Low maintenance

- Small footprint

- Few parts subject to wear

- In comparison with bucket elevators or pneumatic conveying systems, VE Vertical Screw Lift Systems have the most compact overall dimensions, are easier to maintain, require the lowest number of spare parts, and offer the best price-performance ratio.

Resources