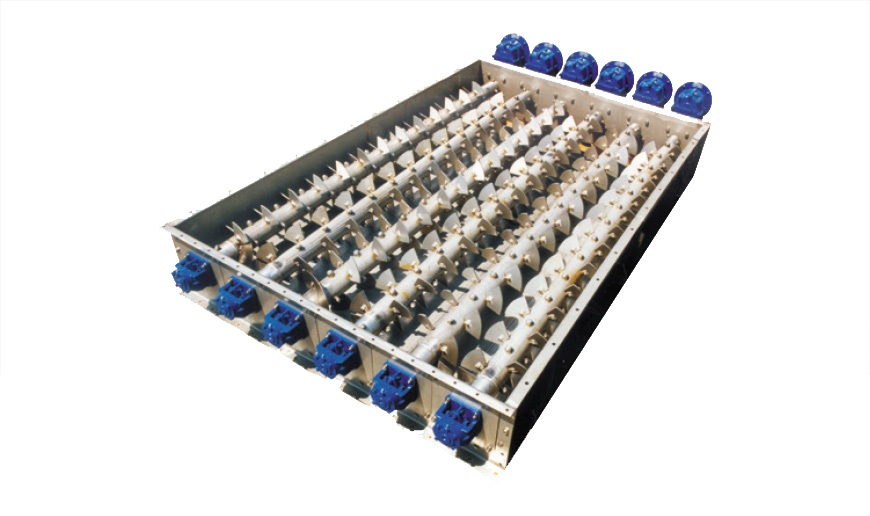

WAM Live Bin Bottoms – MU

MU Live Bin Bottoms are the ideal solution for discharging particularly difficult materials from polygonal hoppers or silos.

MU Live Bin Bottoms (Multiple Screw Feeders) are equipped with a modular trough which encloses up to 6 shafted helicoid flight or paddle screws, externally flanged, fully protected end bearing assemblies complete with manually adjustable packing gland and shaft seal, a rectangular outlet spout covering the entire width of the bin bottom, bolted end plates, splined shaft couplings for medium heavy-duty, and flanged shaft couplings for the heavy-duty version.

Furthermore, MU Live Bin Bottoms are equipped with one gear motor per screw shaft or, depending on the application, with a drive unit driving more screws.

Features

- Robust design

- Screw diameter: 150 ~ 600 mm (6 ~ 24 in)

- Up to six screws in one trough

- Open trough length ranging from 1,500 to 4,000 mm (5 ~ 13 ft)

- Trough housing and screws manufactured from carbon steel, stainless steel or SINT engineering polymer (screws only)

- For certain applications screws and trough lining manufactured from SINT engineering polymer

- Medium heavy-duty or extra heavy-duty helicoid flight screws or paddle screws

- Medium heavy-duty or extra heavy-duty trough in modular flanged sections

- Vertical outlet spout with rectangular cross section or open trough flush outlet both with integrated, drilled WAM standard flanges

- Robust flanged cast iron end bearing assemblies with external bearings and manually adjustable packed gland seals

- Splined shaft couplings (medium heavy-duty); flanged shaft couplings (extra heavy-duty)

- Independent direct compact gear motor drive for each screw

Benefits

- Promotes mass flow

- Gives widest possible material extraction surface

- Avoids bridging

- Avoids segregation

- Provides constant material extracting and feeding even with most difficult materials

- Constant feed rates

- Modular design enabling easy access and individual design features

- High degree of self-cleaning

Resources