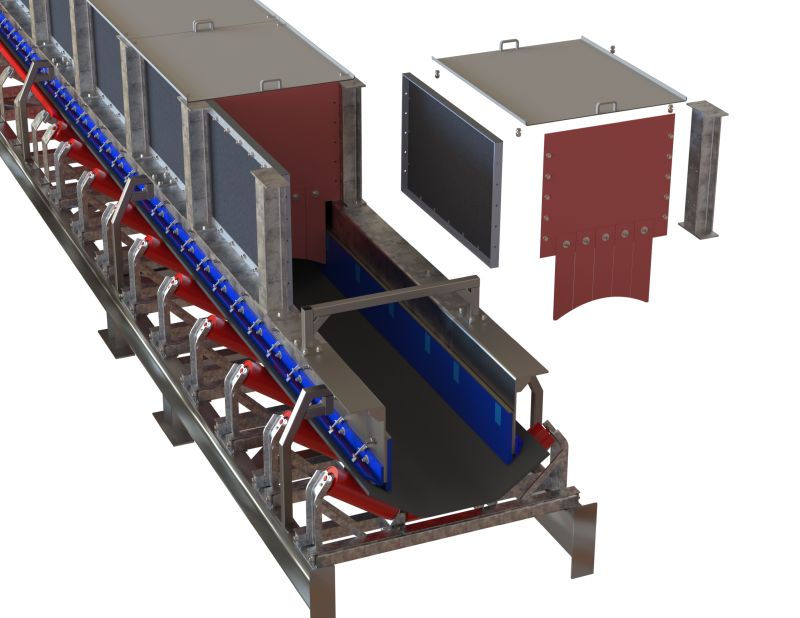

Kinder DustScrape Containment

DustScrape emerges as a tailored solution, effectively resolving and mitigating dust formation.

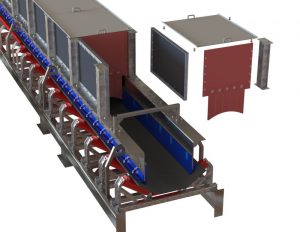

Within enclosed transfer points on conveyor systems, high pressure can build up which can in turn generate significant dust emissions. DustScrape emerges as a tailored solution, effectively resolving and mitigating dust formation.

DustScrape utilises a filter cloth that captures fine dust particles produced within bulk material transfers, allowing air permeability to accommodate resulting overpressure. Reducing the pressure whilst containing the dust allows for a settling of the bulk material.

Available in poly warp and stainless steel option, DustScrape is highly efficient in countering dust and can be tailored to specific environmental conditions.

Key Features

- Available in poly warp and stainless-steel option.

- Simple to install.

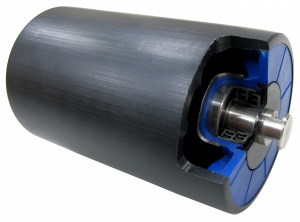

- Suits all conveyor belt widths.

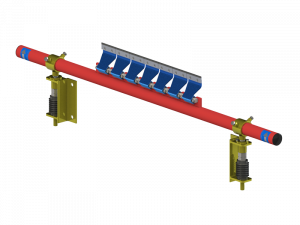

- Maintenance-free and operates without direct contact.

- Unique self-cleaning feature enables prolonged dust retention.

- Effective against dust up-drift.

- Can be used with dust extraction systems.

Related Products

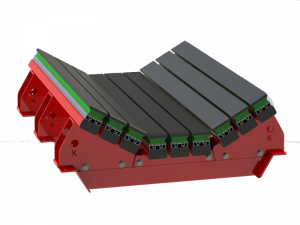

AirScrape®

DustScrape offers a hassle-free solution to dust-related challenges. With easy installation, durability, and maintenance-free, contact-free operation, it seamlessly integrates with existing dust collection systems.

When paired with AirScrape®, the patented sidewall seal (not included), forms an exceptionally effective system that combats dust generation, contributing to enhanced occupational safety and environmental protection. DustScrape ensures dust-free conveyor belt operation at a cost-effective rate, eliminating the need for additional energy input.

Resources

PDF, 538KB