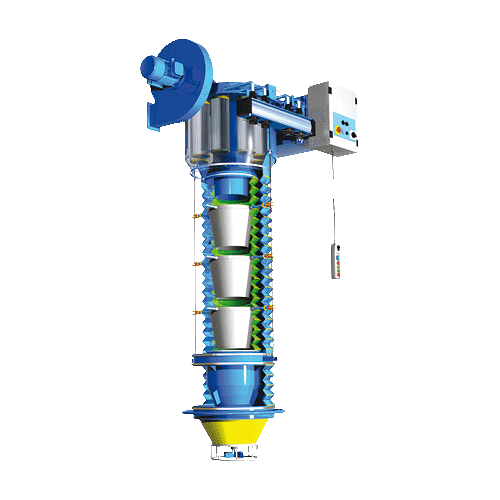

TOREX BELLOJET ZA – Tanker Loading Bellows With Integrated Dust Collector

The ideal solution for efficient, dust-free loading of dry, dusty bulk solids into tankers.

BELLOJET ZA Loading Bellows are used for efficient, dust-controlled loading of dry, dusty bulk solids into tankers. The spouts are provided with inner tapered cones to contain the flow of material and an outer double bellows to provide for dust removal. At the lower end of the Loading Bellows, a SINT engineering polymer-coated cone with special sealing properties is provided for connection to the tanker.

- Reduced dust emission during loading operation

- Weather-proof, durable, highly abrasion and temperature-resistant flexible neoprene chute

- Two lifting cables outside material flow

Features

- Inlet diameter: 300 mm (12 in)

- Maximum throughput rate: 250 m3/h (147 cfm)

- Operating temperature: -40 ~ 150 °C (-40 ~ 300 °F)

- Filter surface: 10 m2 (108 sq ft)

Benefits

- Built-in dust filter reducing dust emission during loading operation

- Flexible chute in Neoprene covered by Hypalon® makes the bellows weather-proof, highly abrasion and temperature-resistant and durable

- Reverse cone with inside level control indicates when tanker is full, gradually raises loading bellows improving material distribution inside the tanker

- Two lifting cables outside the material flow raise and lower the loading bellows without any cable wear due to material friction and obstruction to material flow

Options

- ATEX-version available

- Various chute and fabrication materials available according to material handled

- Control panel with remote control

- Available with different types of level indicators

- Outlet vibrator

- Anti-spillage device (acts as dustproof stopper as loading bellows is being raised)

Industries

- Building & Construction

- Feed & Seed

- Plastics & Chemicals

- Heavy Industry

- Plants & Machinery

- Environmental Technology

Videos

Resources