Torex Pipe Couplings – GT

Safe, quick couplings

GT Couplings are designed to join together two plain pipe ends on the same horizontal axis in a safe, quick and rigid way.

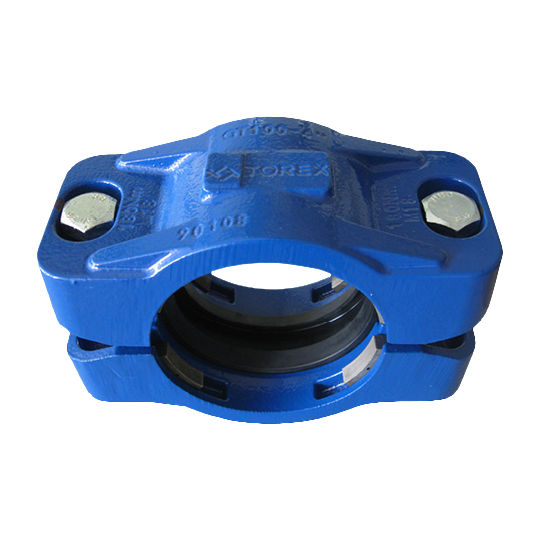

GT Pipe Couplings consist of two cast iron semi-casings with heavy-duty jaws set into the casing halves to secure the pipes together in a safe, quick and rigid way.

The two semi-casings are joined together by strong bolts and nuts positioned on the two ends.

Sealing is ensured by gaskets made from EPDM or food-grade SILICONE.

GT Couplings are designed to join together two plain pipe ends on the same horizontal axis in a safe, quick and rigid way. The jaws set into the casing ensure solid grip and prevent the pipes from pulling out.

Features

- Operating temperature: -40 ~ 110 °C (-40 ~ 230 °F)

- Operating pressure: min. -0.5 bar / max. 7 bar (min. -7.2 PSI / max. 102 PSI)

- Diameters ranging from 40 up to 200 mm (from 1½ in up to 8 in) to meet most common pneumatic line ducts

Benefits

- Quick and easy to install

- Reduced installation costs as compared to welded junctions

- More flexible than welding (GT coupling detachable and re-usable allowing easy and quick modifications of the pipe duct, or can be installed in other pneumatic ducts)

- Compact overall dimensions

- No pressure drop along pneumatic line

- No contamination due to silicone gasket

- Suitable for all pipe thicknesses

- GT coupling can be rotated to provide easy access to nuts and bolts

- Maintenance-free

Resources