WAM

The WAM brand, which gave the Group its name. stands for designing and manufacturing screw conveyors, dust collectors and intercepting valves for powders and granular materials.

WAM has been represented in Australia by its own subsidiary since 1997. Responsible for distribution of the bulk solids handling and processing product range in Australia, Papua New Guinea, New Zealand, and parts of Micronesia. It is the goal of WAM Australia to provide with quality products that are specifically tailored to the different needs of a variety of industries.

Products

Bulk Materials Dischargers

Dust Collectors & Filters

Flanged Round Dust Collectors

WAMFLO

The WAMFLO Dust Collector range is the result of WAM’s decades of experience in dust filtration technology. In diverse configurations WAMFLO has proved to be suitable for a variety of applications in virtually all industries. Used for both venting and suction applications.

WAMFLO Food

WAMFLO Food FN200 Dust Collectors are equipped with a cylindrically shaped stainless steel casing and welded flanged bottom ring which contains vertically mounted filter bag elements of various types of fabrics which are all food-grade and certified.

WAMFLO Vibrated

Easy Bin or Silo Venting Without Compressed Air. The WAMFLO Vibrated Venting Filter range has been designed for installation on top of silos, bins and hoppers, which are pneumatically filled by tankers or blowing pumps.

Hopper Venting Filters

Venting Filter – HOPPERTOP

The perfect solution for weigh hopper venting in concrete batching plants combining a particularly small footprint with advanced dust filtration technology.

Venting Filter – HOPPERJET

A polygonally shaped, small footprint venting filter for installation on intermediate storage hoppers or weigh hoppers.

Polygonal Dust Collectors

Polygonal Dust Collectors

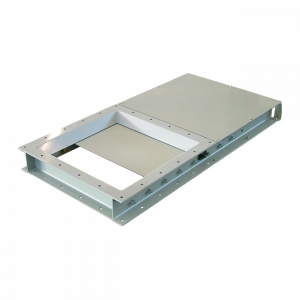

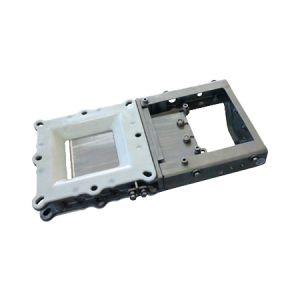

WAMAIR Dust Collectors consist of a polygonally shaped 304 stainless steel casing, horizontally or vertically inserted filter elements, and a reverse air jet cleaning system integrated in the hinged front easy access door. WAMAIR Dust Collectors are either built in for venting applications or come as a stand-alone unit with dust collecting hopper.

Insertable Polygonal Dust Collectors – WAMAIR Vacuum

WAMAIR Vacuum is a polygonally shaped Dust Collector for negative pressure pneumatic conveying applications. Filtering elements are inserted horizontally or vertically while a compressed air cleaning system is integrated in the access door. WAMAIR Vacuum is the ideal Dust Collector for negative pressure pneumatic conveying applications.

Silo Venting Filters

SILOTOP Silo Venting Filters

WAM SILOTOP silo venting filters provide efficient dust control and venting for silos, ensuring clean and safe operations by preventing dust emissions during material loading and unloading.

Silotop Zero Venting Filter

A cylindrically shaped dust collector for venting pneumatically filled silos. Its stainless steel body contains vertically mounted POLYPLEAT elements made from ABSOLUTE filter media. The air jet cleaning system is integrated into the hinged weather protection cover.

Polygonal Silo Venting Filter with Shaker Cleaning – DUSTSHAKE R03

Economical Dedusting Solution in Absence of Compressed Air.

WAMFLO Vibrated

Easy Bin or Silo Venting Without Compressed Air

Valves

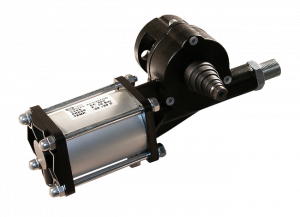

Actuators

Butterfly Valves

Butterfly Valves – VFP / VFPX

VFP/VFPX Butterfly Valves can be fitted beneath hoppers, bins, silos, screw or other type conveyors, or to intercept pneumatic conveying ducts. Due to their special design material residue between valve and the connected feeding device is drastically reduced.

Butterfly Valves – VFS

VFS Butterfly Valves consist of two high-pressure die-cast semi-bodies manufactured from aluminium alloy, a swivel disc in SINT polymer composite or cast iron, and a prestressed elastomer seal.

Silo Closure Butterfly Valves – VFF

VFF Carbon Steel Butterfly Valves are used to shut off the outlets of building material silos. Their sturdy design allows easy and quick installation.

Butterfly Valves – VW

WAM’s VW Butterfly Valves consist of a single block body manufactured from die-cast aluminium, a carbon 304 stainless steel disc including shafts and an elastomer seal.

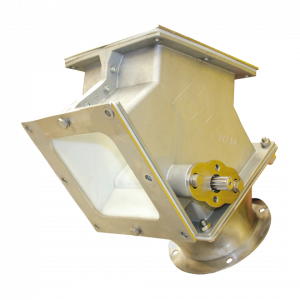

Paddle Wheel Valves – VFD

The VFD Paddle Wheel Valve made of aluminum-alloy, stainless-steel and NBR components, offers optimal balance of quality, ease of maintenance, safety, environmental compliance and cost effectiveness to meet market demands.

Diverter Valves

Pressure Relief Valves

Pressure Relief Valves – VHS

The VHS membrane silo pressure relief valve provides a safety net when abnormal pressure conditions endanger the silo structure.

Membrane Pressure Relief Valves – VHS-C

The Polymer membrane silo pressure relief valve ensures the filling of a silo does not allow abnormal pressure conditions to endanger the silo structure.

Pressure Relief Valve – VCP

The spring loaded silo pressure relief valve handles sudden excess or suction pressures that can develop in the silo, hopper or bin.

Pressure Relief Valve – VCP-D

The spring loaded silo pressure relief valve is made from polymer and are built to handle sudden excess or suction pressures that can develop in the silo, hopper or bin.

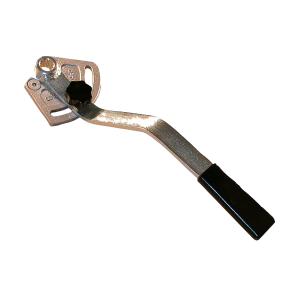

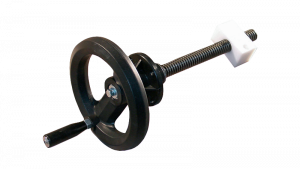

Slide Gate Valves

Screw Conveyors & Feeders

Micro-Batch Feeders

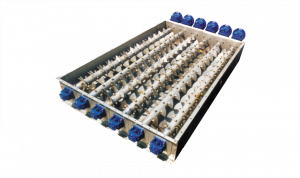

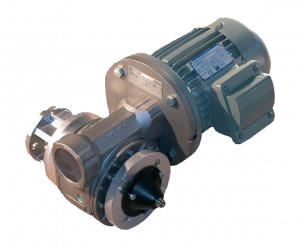

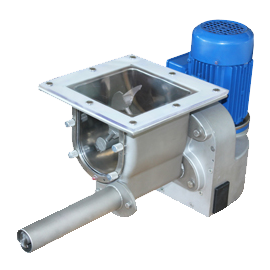

Micro-Batch Feeders with Agitators – MBF

MBF Micro-Batch Feeders are particularly suitable for feeding poorly flowing powders and granular materials which tend to clog. A comprehensive modular system design ensures the right solution for virtually all user requirements.

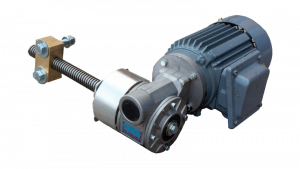

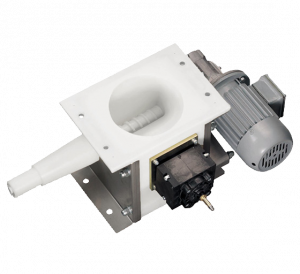

High Efficiency Micro-Batch Feeders – MBH

MBH is the most versatile and economic solution for high efficiency micro-batch feeding. It is available in 3 different versions (standard in 316 SS, with SINT™ engineering polymer chamber and feeder pipe and a version for Food applications with ATEX and EC 1935/2004 certification).

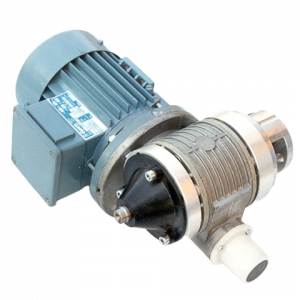

Micro-Batch Feeders – FLEXFLO

MBW Micro-Batch Feeders are particularly suitable for feeding free or moderately flowing materials which do not tend to pack under pressure in a variety of industries, among which plastics processing, animal feed milling, as well as waste water and drinking water treatment.

Trough Screw Conveyors & Feeders

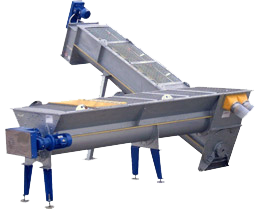

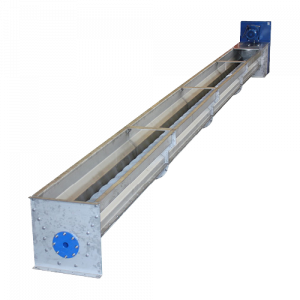

Trough Screw Conveyor – CX

The modular CX Trough Screw Conveyor system offers a variety of solutions for conveying or feeding powdery or granular materials.

Tubular Trough Screw Conveyor – CAO

The light-duty version CAO, is mainly used for feeding and conveying flour and flour milling by-products.

Shaftless Screw Conveyor

The SSC Shaftless Screw or Spiral Conveyor is an alternative concept to the traditional shafted screw conveyor.

Trough Screw Conveyors – CA

Special configurations from standard components

Trough Screw Conveyors for Flour Mills – MSC

Designed for flour mills

Trough Screw Conveyors for Animal By-Products CLO-CLOS

Robust and reliable

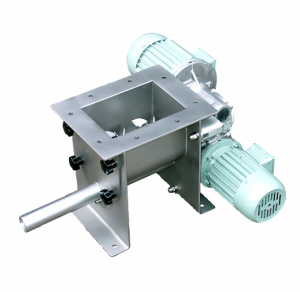

Twin Shaft Screw Feeders – BU

BU Twin Shaft Screw Feeders are an option for users who require particularly efficient discharging/feeding from bins or hoppers.

Tubular Screw Conveyors & Feeders

Tubular Screw Conveyors – TU

The modular TU Tubular Screw Conveyor and Feeder system is highly versatile offering a variety of standard solutions for handling of powdery or granular materials.

Filler Dust Screw Feeders & Conveyors – THF / TCF

THF / TCF Screw Feeders and Conveyors for Filler Dust are designed to match the main requirements of the asphalt industry.

Cement Screw Conveyors & Feeders – ES

ES Screw Conveyors and Feeders are used for conveying or feeding cement and materials similar to cement mainly in concrete batching plants but also in other building materials processing plants.

Stainless Steel Tubular Conveyor – TX

The TX Tubular Screw Conveyor system offers a variety of solutions for conveying or feeding powdery or granular materials.

Minimum Residue Tubular Screw Feeders – EASYCLEAN

EASYCLEAN are specialised Screw Conveyors and Feeders entirely manufactured from stainless steel.

Heavy-Duty Tubular Screw Conveyors – TP / TE

TP / TE Tubular Screw Conveyors are used for both batch and continuous operation in applications where durability and easy replacement of those conveyor components that are subject to wear are among the main requirements.

Vertical Screw Conveyors

The VE Vertical Screw Lift System consists of two units: a Horizontal Screw Feeder which receives material from a silo, hopper, or another feeder or conveyor, and a Vertical Screw Conveyor that lifts the material to a certain height.

Wastewater Treatment

Contact us about WAM Products

Please contact us using the form below or send us an email.