Smarter Silo System Transforms Bulk Handling in Kwinana

A fully automated silo and bagging upgrade delivered cleaner operations, faster turnaround, and safer working conditions for a busy bulk handling site.

Problem

Increased production demand required a cleaner and more efficient method for transferring and bagging bulk materials. The previous system relied on operators manually filling bags with a front-end loader, creating excessive dust, downtime, and safety risks.

Dust leakage also raised health and explosion hazards, making a reliable dust collection system essential for compliance and worker safety.

Solution

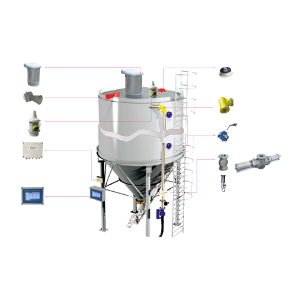

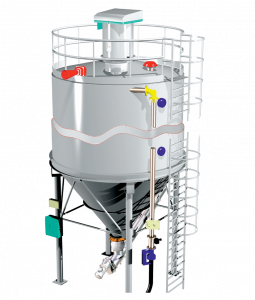

Inquip designed and delivered a 35m³ storage silo system complete with a dust collector, level sensors, and a semi-automated filling control system integrated with a customised bulk bag filler (FIBC) and weighing scales.

Working with Automation & Control, the system was engineered for precise product measurement and improved plant efficiency while reducing manual handling.

Key results included:

- Increased bulk storage capacity.

- Over 50% reduction in manual handling time.

- Simplified and more accurate filling through automation.

- Elimination of OHS and dust-related safety concerns.

Impact

The new system enabled faster, safer, and more accurate bag filling operations. Automating the process improved reliability, reduced downtime, and enhanced operator safety — delivering long-term economic and operational benefits for the customer.