Reliable Paste Backfill Mixing for Underground Mining

Inquip delivered a series of continuous Ploughshare Paste Fill systems designed to improve reliability, reduce maintenance, and boost productivity in underground mining operations.

Problem

As demand for paste backfill stope filling grows across the underground mining sector, so does the need for more efficient and reliable mixing systems.

Traditional twin-paddle and pugmill mixers often caused excessive wear, cement build-up, and long cleaning downtimes — creating costly interruptions and OHS risks for maintenance crews required to manually clean inside the mixing chamber.

Solution

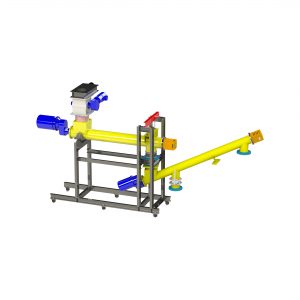

Inquip supplied a Continuous Single-Shaft Ploughshare Mixer, providing a faster, cleaner, and more consistent paste mixing process. The high-speed shaft and plough tools deliver a vigorous mixing action that homogenises tailings and binders to achieve a uniform, high-quality paste with repeatable MPA performance.

The system’s self-cleaning capability eliminates manual entry for cleaning — when rinsed with water, the high-speed mixing action naturally cleans the chamber and tools through cavitation, avoiding blockages and removing the need for high-pressure wash systems. This design significantly reduces maintenance time, safety risks, and downtime between production cycles.

Impact

The new paste fill mixing system increased operational reliability and boosted production output by 25–50% per day, while reducing labour and maintenance costs. Operators report improved performance, consistent paste quality, and a safer working environment.

Inquip continues to support mining operations with integrated paste fill systems, including silos, binder feeding, and weighing solutions — delivering reliable, low-maintenance performance across Australia’s toughest applications.