Bulk Materials Dischargers

Our bulk materials discharging solutions are engineered to enhance industrial operations, providing efficient and reliable material transfer.

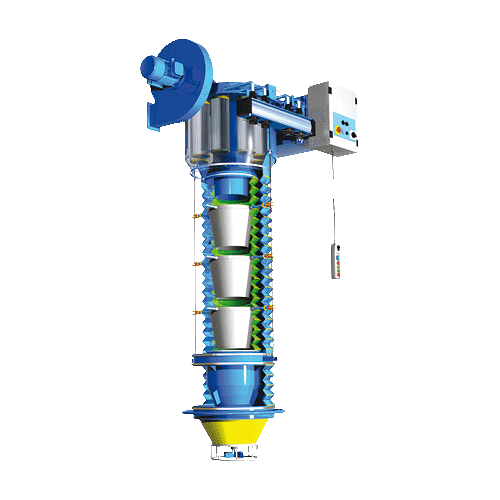

Our bulk materials discharging products increase productivity by facilitating swift and controlled material transfer, precise weighing to minimise waste, and versatility in handling diverse material types. The automation features reduce manual labour, contributing to a safer working environment, while advanced technologies ensure precise control over material flow, preventing blockages and maintaining a consistent production pace. Additionally, the focus on cost-efficiency optimises material handling processes, making these solutions a valuable asset for industrial facilities seeking streamlined operations.

Product can be delivered to and from site in a variety of different vessels, from 18 and 25kg bags, to FIBCs, silos and pneumatic tankers. Each has their own difficulty, be it dust, clumping, loss of product, degradation or contamination.

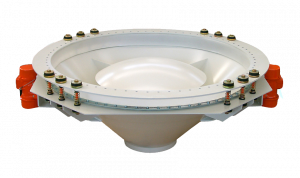

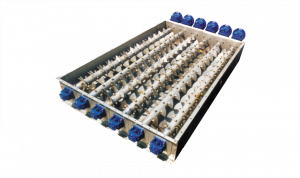

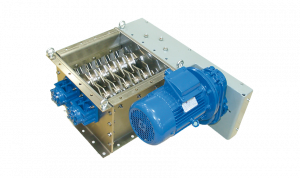

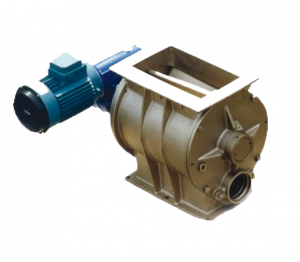

Inquip can review any materials handling application and provide a tailored solution to effectively remove or fill product into almost any vessel. The WAM range of discharge equipment includes manual bag splitters with inbuilt dust collectors, FIBC bag loaders, FIBC bag unloader, silo bin activators, automatic loading bellows (with / without inbuilt dust collectors).

Products