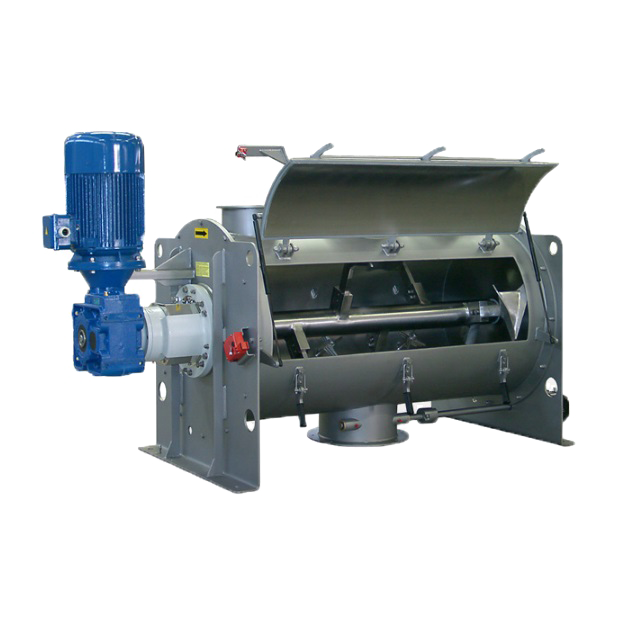

MAP Single Shaft Mixer – WBH

The WBH Batch type Single Shaft Industrial Mixers are the ideal machine to obtain highest quality mixtures in perfectly reproducible batches. MAP also provides mixing tests for customers in the companies own laboratories currently in more than fifteen countries.

WBH Horizontal Single Shaft Batch Mixers consist of a mixing drum with an inlet, an outlet with discharge valve and a venting spout, a full material mixing shaft, two drum closing end plates that carry flanged end bearing assemblies complete with integrated air or gas-purged shaft seals, and a drive unit complete with power transmission.

The WBH Batch Industrial Mixer is based on the principle of mechanical fluidisation of the product.

The specific shape, position and rotation speed of the mixing tools, creates a centrifugal vortex motion which moves the materials in a three-dimensional way to merge with each other. This ensures that ingredients with different particle sizes and bulk densities are perfectly blended and mixed with high precision within the shortest time possible.

WBH Batch-type Mixers are used for mixing dry powders, granules or short fibres, for moistening, agglomerating or granulating the same materials, or for mixing liquids or low viscosity pastes.

Videos

Applications

Features

- Model sizes with capacities from 10L/batch to 20,000L/batch.

- Variation Co-efficient achieved (CV) of 3 to 5%.

- Ability to add up to 20% liquid to the batch mixing process.

- End bearing assemblies available with various types of air or nitrogen-purged shaft seals or grease sealing.

- Available in Carbon Steel, Anti-wear steel, Stainless Steel 304 and Stainless Steel 316 constructions.

- Available in bead blasted, mirror polished or grit silked finishes.

- Wide range of mixing tools fittable including ploughshare, toothed ploughshare, blade-type, toothed blade all possible with anti-wear coating on request.

- Available with Replaceable liners, Ceramic liners, Teflon liners and Stainless steel mesh as optional additions.

- Optional pneumatic sampling devices available to be fitted.

Resources