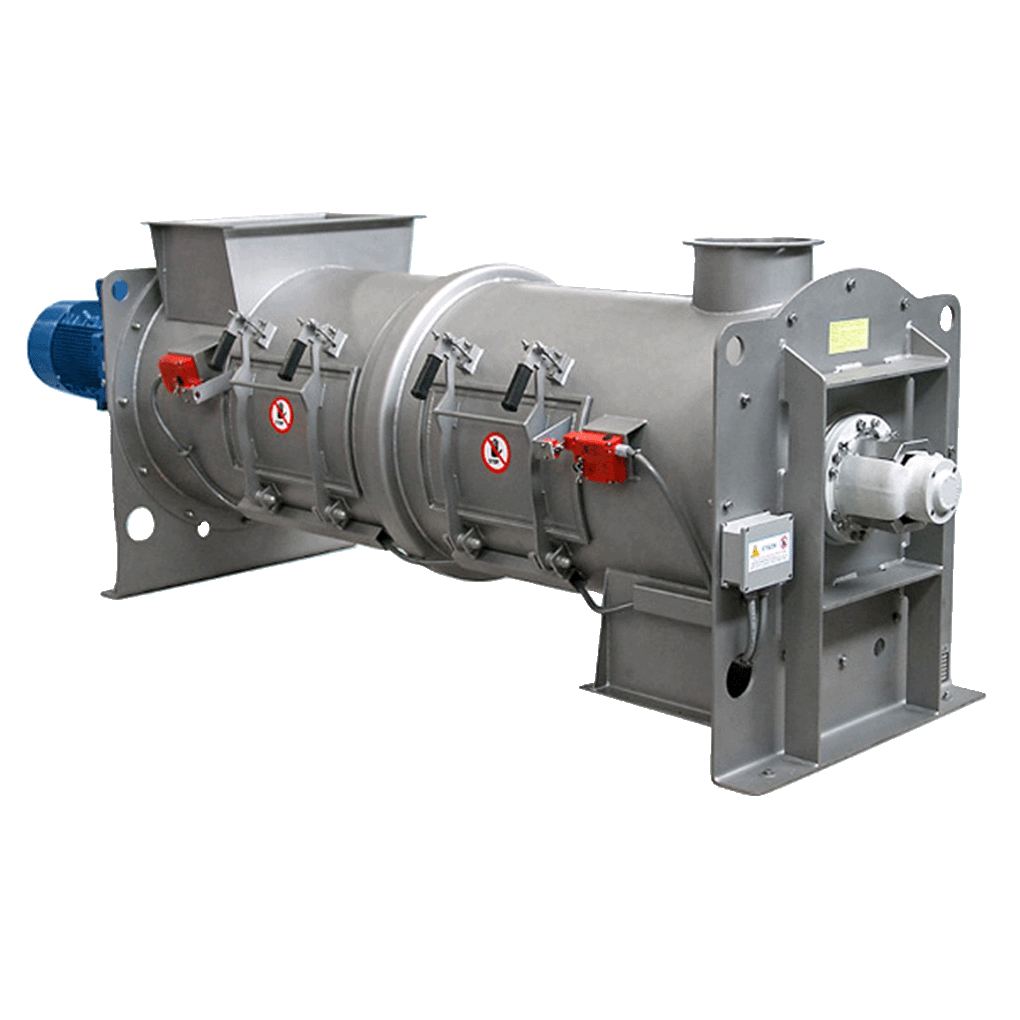

MAP Continuous Mixers

Inquip supply continuous mixers in both single shaft and twin shaft paddle for an uninterrupted stream of ingredients, which are used in a variety of industries.

The process of continuous mixing involves a large piece of industrial equipment that has a continuous mixing motion. The weighing, loading, mixing and discharge steps occur continuously and simultaneously. Continuous mixers are dedicated to producing a single high-volume product. Ingredients are continuously fed to the mixer according to a formula, with the mixing taking place as the material moves from the charging port to the discharge nozzle.

Continuous mixers have many advantages which include high capacity compared to batch mixers, lower mixing time is required, and the mixing performance is much more consistent with proper feeding arrangements.

These advantages eliminate the problems associated with batch cycles, producing a consistent product all day, every day. Making continuous mixers an ideal solution in a variety of different industries including food production, chemical manufacturing, pharmaceuticals, and plastic/ composite production.

Products