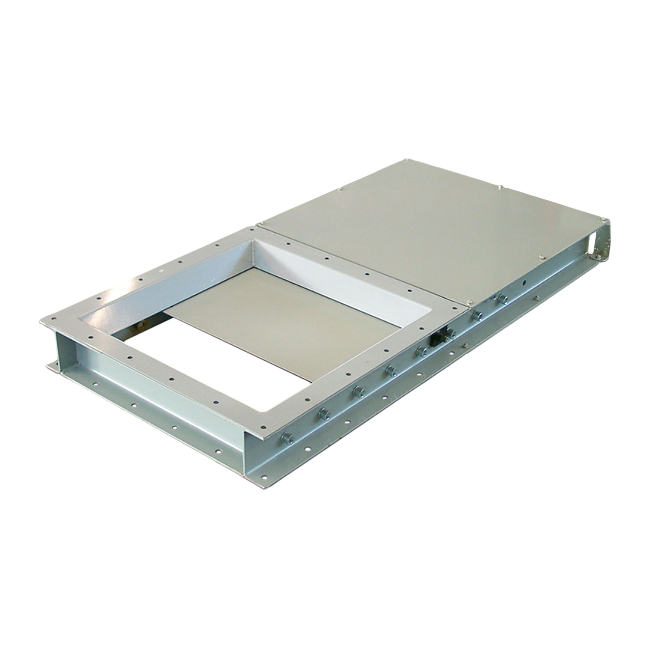

WAM Heavy-Duty Slide Gate Valves – VG

A perfect solution for all heavy-duty applications where interception of gravity material flow is required. They are suitable for virtually all industrial sectors including the food industry.

Slide Valves are ideal for handling a wide range of materials in countless industries. They are particularly popular for handling dry bulk materials in large quantities, a slide valve is the option to choose powders, granules, pellets and grains plus many other dry materials.

VG-type Slide Valves are entirely manufactured from carbon steel or stainless steel. Safe material interception and excellent durability are guaranteed. This type of valve is designed to meet the most demanding applications when handling abrasive materials such as sand, gravel, coal, or whole grain in heavy-duty applications. The ideal equipment for gravity applications, VG-type Slide Valves are available in larger sizes than the VL-type (refer to relevant page). They are equipped with two replaceable, abrasion-resistant seals. The valves are available in various configurations. In the VG-version the Slide Valves come with a square cross section, in the VGR version the cross section is rectangular.

Features

- Carbon steel or stainless steel valve frame and blade

- Limited number of components

- Quick and easy maintenance

- Painted carbon steel frame prevents rusting

- Sizes of up to 1,000 x 1,000 mm (3.3 x 3.3 ft)

- Interchangeable actuators: manual, pneumatic or electric gear motor

- Service inlet to deflect material away from seals and rollers to reduce wear

Benefits

VG Slide Valves provide reliable, long-term operation in applications where carbon steel slide gates generally tend to corrode. Traditional roller-supported slide gates are usually equipped with ledges where material can build up. VG Slide Valves come without ledges, thus minimising material cross-contamination and spoilage.

Models

VG

Slide Valve

- VG 0500

- VG 0600

- VG 0700

- VG 0800

- VG 1000

VGR

Rectangular Slide Valve

- VGR 0150

- VGR 0200

- VGR 0250

- VGR 0300

- VGR 0350

- VGR 0400

VGM

Push Slide Valve

Resources