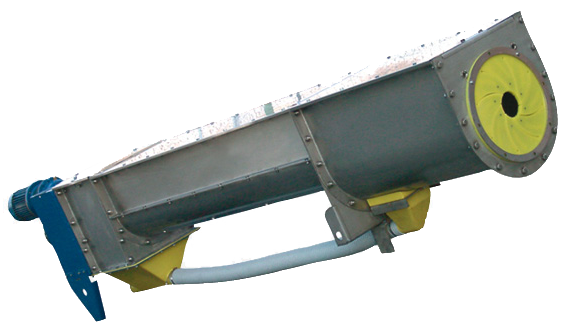

Screw Compactors – WASTECOM CPS

Screw Compactors consist of a conveyor trough manufactured from stainless steel, a shaftless extra heavy-duty spiral manufactured from carbon steel, a compacting and de-watering discharge module, a return duct for pressed out water, and a drive unit suitable for the application.

Three functions in one unit: conveying, de-watering and compacting. Designed for intermittent operation, WASTECOM CPS Screw Compactors can be employed in various de-watering applications and in combination with different type solids-liquid separators or conveyors. Usually applied for compacting various solids from different processes.

Industries

- Municipal/industrial waste water treatment

- Food processing

- Slaughterhouses

- Rock wool industries

- Plastics recycling processes

Benefits

- Two functions: conveying and compacting

- Up to 40% reduction of screenings volume

- Particularly maintenance-friendly modular design

- No machine locking even with fibrous materials

- Fully enclosed, pollution-free, odour-free

- Low noise level

- Low energy consumption