Benefits & Maintenance of Loading Bellows

Discover how loading bellows improve dust control, material flow, and safety in bulk materials handling operations.

What are Loading Bellows?

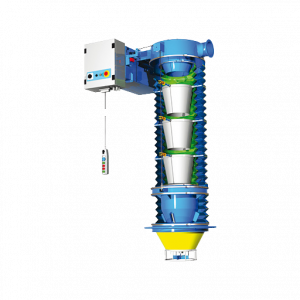

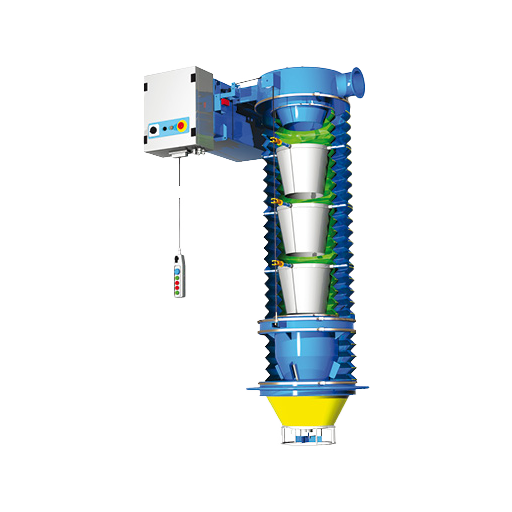

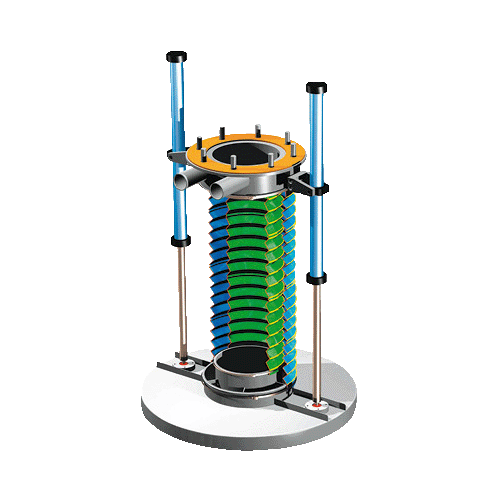

Loading bellows — also known as telescopic loading spouts or chutes — are specialised attachments used in bulk materials handling to facilitate controlled, dust-free loading of dry bulk solids into vessels such as tankers, trucks, ships, and stockpiles. They are designed to contain material flow, reduce dust emissions, and minimise material loss and safety risks during loading operations.

How Loading Bellows Work

Loading bellows consist of a flexible telescopic chute with an inner tapered cone to guide bulk material, and an outer bellows assembly to capture and control dust. During operation:

- The bellows are lowered toward the receiving vessel.

- Once the outlet cone seats on the vessel inlet (e.g., tanker or truck), material flow begins.

- As the vessel fills, the bellows extend and retract to maintain contact and seal.

- Dust is either directed to an external dust collector or contained via integrated filtration.

Key Benefits

Loading bellows offer several advantages for bulk handling operations:

- Dust control: Prevents material escape and improves workplace safety.

- Improved distribution: Internal cones help evenly distribute material within the vessel.

- Weather and abrasion resistant: Flexible chutes (e.g., neoprene with Hypalon®) are built for durability in harsh environments.

- Reduced maintenance: Lifting cables are positioned outside the material flow to reduce wear.

Typical Applications

Loading bellows are ideal for industries such as:

- Building & construction

- Mining and minerals processing

- Feed and food

- Heavy industry

- Environmental technology

- Port and shipping facilities

Choosing the Right Loading Bellows

Our engineering team can assess your application to recommend the best configuration. When selecting loading bellows for your operation, consider:

- Material type (dusty vs non-dusty)

- Throughput requirements

- Connection type (tanker, truck, ship, stockpile)

- Dust control needs

- Site conditions and temperature range

Types of Loading Bellows (and When to Use Them)

Loading bellows can be grouped into five main types based on how and where they’re used in bulk materials handling. Each type solves specific challenges — from dust control to high throughput or open truck loading.

Tanker Loading Bellows

These bellows are designed to provide a sealed connection between the loading point and tanker inlet, reducing dust emissions and improving safety.

Best for: Dust-controlled loading of bulk materials into tankers and road vehicles.

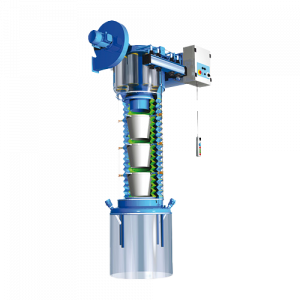

Open Truck Loading Bellows

These bellows are built to handle heavy product flow and dynamic truck loading situations — while keeping dust contained close to the source.

Best for: Loading bulk materials into open-top trucks without excessive spillage or dust.

Ship & Stockpile Loading Bellows

These units are engineered for high throughput and long-reach flexibility, often paired with external dust extraction systems.

Best for: High-capacity loading into ships, barges, stockpiles, or large receptacles.

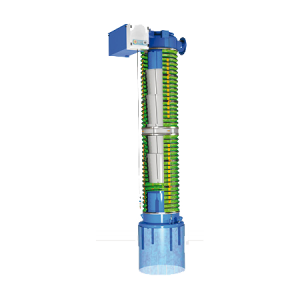

Small-Scale / Portable Loading Bellows

Compact solutions that still provide controlled flow and reduced dust for smaller containers.

Best for: Lower volume operations, drums, IBCs, and small-scale batch loading.

Featured Products